News about WERMA

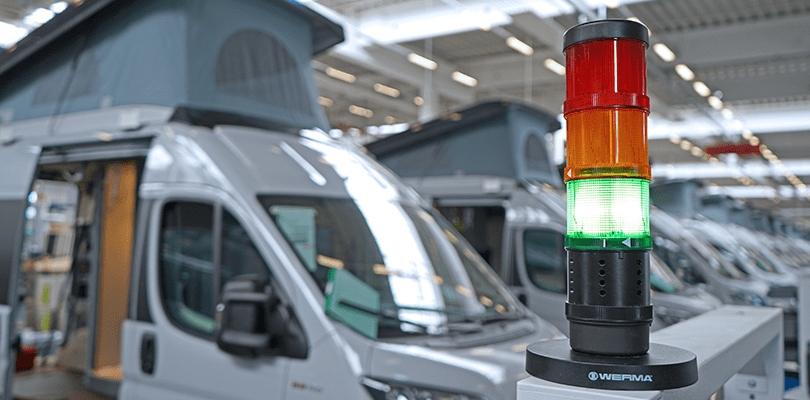

Success Story: Safe production at HYMER thanks to CO2 traffic lights

The motorhome specialist uses WERMA CO2 traffic lights to ensure the health and safety of all persons present

HYMER – quality, comfort and cult status since 1957

"Camper van travel is more than a vacation – it’s a passion", says Markus Bächle, Team Leader of Maintenance and Repair at the HYMER Electrical Workshop, with a twinkle in his eyes. "So our customers are entitled to receive a vehicle of the highest standard – whether we are talking about comfort, quality, safety equipment, comprehensive features or value retention." It is immediately obvious that the engineer is not only a fan of HYMER and their production processes, he adores the whole world of caravanning. He enthusiastically explains the individual production and assembly steps, describes the materials used and gives us insights into the training workshop. " 'Made in Germany' is not just a phrase for us, we really put it into practice – everything is produced in Germany. This guarantees outstanding quality for our customers and a high degree of independence for the company." Smiling, he adds: "In fact, it would be even more accurate for us to say 'Made in Bad Waldsee'!"

As the inventor of the motorhome, HYMER has built premium-quality recreational vehicles since 1957 and enables their customers to experience unique trips and holidays. From practical camper vans to premium motorhomes, the company has the right vehicle for any requirement. HYMER guarantees high-quality vehicles with the highest levels of comfort and technology. HYMER’s mission has always been to set new standards, whether for safety, lightweight construction or insulation.

Caravanning: More freedom in times of a pandemic

For months now, the COVID-19 pandemic has acutely curtailed not only the German economy, but all areas of life and the entire country. The pandemic has also left its mark on HYMER. On one hand, the company was delighted that the order books were full and that caravanning as a hobby was experiencing increased popularity but,says Bächle, "at the moment, we can't produce enough to meet market demands".

The company, like many others, has also had to contend with supply bottlenecks, coronavirus in the workforce and the strict requirements of the regulatory and health authorities. "Of course, we are very keen to protect the health of all our employees", says the maintenance technician. "It’s our top priority to avoid infections in the workplace and to make everyone on site feel safe and happy."

When asked what measures HYMER introduced to ensure this, Bächle replied: "We met the requirements of the authorities and equipped our trainees with CO2 measuring devices. They spent all day every day for three months measuring the CO2 values in the ambient air in all areas of the company. We just wanted to prove that our air quality is fine and that we protect our employees from infection in the workplace as far as possible."

The goal: Reliable air quality values

The company went one step further and looked for an even more precise solution: "We simply wanted to display the current status of air quality continuously and reliably to all those present", says Bächle. "The measurements taken by our trainees did indeed show that we generally have very good values, but these measurements were too sporadic, not reliable enough and, above all, not visible to the employees on site."

The head of maintenance therefore started looking for suitable equipment to continuously measure the CO2 content in the ambient air and to present it clearly and visibly to all. He came across the solution provided by the signal device manufacturer: "We already knew about WERMA. After all, we have been using their signal towers and the SmartMONITOR wireless-based machine monitoring system for a long time and are completely satisfied with these clever solutions."

Ordered today, installed tomorrow

"Naturally, we also looked at alternative products", says Markus Bächle. "However, the light elements or signals they used were far too small to be noticed in our large production halls. " Some other products were not accurate enough, according to the head of maintenance. "We didn't need to think about it for very long and immediately ordered 12 CO2 traffic lights from WERMA for an initial test run. These were put through their paces in a separate production area." Markus Bächle adds that the employees were immediately impressed with this type of display. "The traffic lights hang centrally and a little higher up so that they can be easily seen from anywhere. Right away, this put everyone at their ease and, most importantly, made them feel safe."

In the meantime, more than 30 WERMA CO2 traffic lights have been installed in the production halls at HYMER: in wooden components production, the foaming shop, upholstery, pre-assembly, side wall pre-assembly, the training workshop and the huge assembly hall where the vehicles are completed. Here, four CO2 traffic lights are mounted on each of the four assembly lines. A total of 16 traffic lights make a significant contribution to employee safety in the 15,000m² hall.

Clever, safe and visible through 360° – this is how the CO2 traffic light works

WERMA's solution for CO2 measurement in indoor air consists of a three-tier signal tower, which is immediately ready to use and very easy to install. Simply plug in the supplied power supply, wait until self-calibration is completed and the traffic light is ready for use. The current CO2 concentration in the ambient air is measured immediately and displayed using the three traffic light colours.

It continuously measures the current CO2 concentration and displays the results using the three traffic light colours - in accordance with official recommendations from the German Federal Environmental Agency:

- If the CO2 concentration is below 1000 parts per million, the traffic light is green indicating that the air quality is OK.

- If the CO2 concentration exceeds 1000 ppm, the traffic light turns amber and indicates that ventilation is recommended.

- The red signal indicates that ventilation is required as the CO2 concentration has risen above 2000 ppm.

- If the limit of 3000 ppm is exceeded, a red blinking light indicates an acute need for ventilation.

Top air quality at HYMER

Bächle is delighted that the CO2 traffic light is working so well and has been very well accepted: "The traffic light is clear, easy to understand and needs no explanation. Everyone can immediately see when the traffic light signal changes to amber and ventilation is required." Furthermore, the signals are clearly visible from all sides thanks to 360-degree illumination. The extremely bright LEDs guarantee that they are clearly visible, even in direct sunlight and bright surroundings.

Thanks to WERMA's CO2 traffic lights, air quality in enclosed spaces can be improved in the long term, as high concentrations of carbon dioxide and aerosols in enclosed spaces are avoided through regular and effective ventilation. This not only results in a more hygienic environment, but one that is more productive due to improved indoor air quality. "We are pleased that the CO2 traffic light is not a short-term investment for our production halls", says Markus Bächle. "Low CO2 content in the room not only protects against infection, it also improves the concentration and performance of all those present."

WERMA's new CO2 traffic lights not only ensure the highest possible level of safety for employees, customers and visitors, but also promotes long-term productivity and performance.